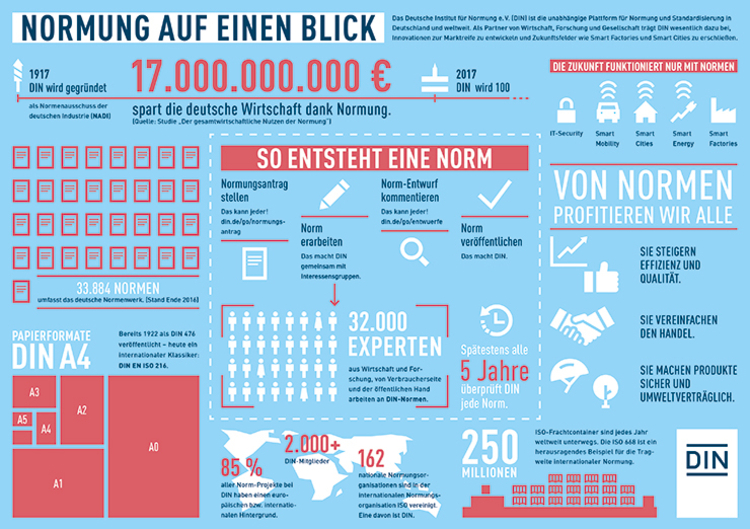

DIN standards

The importance of industrial standards in technical ceramics

The purpose of industrial standards in technical ceramics

Standards provide direction in almost all areas of the industrial environment: for example, with regard to questions of product safety, compatibility with health and the environment, consumer protection, usability and uniform test procedures.

Basic principles of technical standardisation

Standards are the result of a consensus between national, European and international standardisation work. They’re developed by specialist committees at DIN (German Institute for Standardisation), at the European standardisation organisations CEN/CENELEC and at the international standardisation organisations ISO/IEC in accordance with established rules and procedural and design regulations.

Formal framework of standards

DIN standards are based on verified scientific knowledge and experience, while taking into account the state of the art. However, as private regulations they formally only have the status of recommendation. In principle, their application is voluntary – unless the legislator prescribes compliance with standards or where standards form the basis of contracts, in which case these standards then also become binding. In addition, compliance with standards provides security in the event of possible liability: those who base their services/products on standards – as “recognised rules of technology” – are in a better position to prove proper conduct.

Designations of standards

The origin of a standard can be recognised by its name:

- “DIN” – a standard developed by a German standards committee

- “DIN EN” – German adoption of a standard developed by CEN

- “DIN EN ISO” – a standard developed by ISO, adopted by CEN and further adopted by DIN

- “DIN ISO” – German adoption of a standard developed by ISO.

Source:

www.din.de

Important DIN standards for technical ceramics

In addition to providing standardisation, which deals with quality and environmental management systems of industrial ceramic manufacturing companies, standards in this field essentially extend to materials and test methods.

The area of standardisation for technical ceramics includes the following material groups:

- Oxide ceramics (includes mostly synthetically produced metal oxides such as zirconium oxide, aluminium oxide and magnesium oxide with high-temperature resistance, high resistance against wear and corrosion. Applications: structural ceramics, electronics).

- Non-oxide ceramics (compounds of silicon, nitrogen, carbon and boron, e.g. silicon nitride, silicon carbide, boron carbide and boron nitride).

- Silicate ceramics (predominantly SiO2, also clay ceramics: e.g. earthenware/stoneware, porcelain for applications in high- and low-voltage technology as an insulator, for heat engineering and refractories - e.g. fireclay)

Standards for test procedures are structured

- firstly in test procedures based on the structural material composition (powder, layers, monolithic ceramics and composite materials)

- and within these categories, in test methods according to:

Chemical properties (corrosion resistance)

Physical properties (grain size, porosity and density)

Structural/mechanical properties (tribology, surface roughness, bending strength, deformation, change in length)

Electrical properties (conductivity/insulation, dielectric strength)

With international comparison, in particular, it’s important that material data and test results are based on comparable standards. Information in data sheets is always based on standardised measuring methods and is therefore reliable.

When making use of standards, it’s also essential to have precise knowledge of the content of the standard, i.e. be familiar with the text. In Germany, standards must be obtained from Beuth-Verlag – only then is proper use guaranteed. This concerns all types of standards, including EN, ISO and ASTM.

Details of important standards:

1. Relevant standards for management systems

- The international DIN EN ISO 9001 standard defines the requirements for quality management systems and continuous quality checks in companies. A key goal of ISO 9001 is to create trust in the products and services and to increase customer satisfaction.

- Requirements for environmental management systems are certified through DIN ISO 14001. This concerns systematic management of environmental protection, the use of sustainable resources and avoiding climate risks. The entire life cycle of a product, from development through production to recycling or final disposal, is also taken into consideration.

- DIN EN ISO 50001 encompasses requirements for the introduction, implementation and optimisation of energy management systems.

- ISO TS 16949 specifies requirements for quality management systems for series and spare parts production in the automotive industr

2. Material standards for oxide ceramics:

- The (ceramic) materials labeled with DIN EN 60672 are standardised for electrical engineering but are not used only there. The well-known standard predecessor DIN 40 685/VDE 0335 originated from safety aspects and was one of the first standards of ceramic materials. The revised and currently valid DIN EN 60672 regulates terms and grouping, test methods and requirements for individual materials – often for insulation purposes. Type designations for ceramic materials are also assigned here and minimum requirements, such as bending strengths, are specified (for example, material designation C 799 – “aluminium oxide”).

- DIN 40680 – ceramic components for electrical engineering: general tolerances for dimensions, shapes and surfaces.

- DIN 40686 – surfaces of ceramic materials for use in electrical engineering.

- DIN EN 14232 – high-performance ceramics: list with terms, associated definitions and abbreviations. Rough subdivision into silicate ceramics, oxide and non-oxide ceramics.

- ISO 15165 – classification system for high-performance ceramics.

- DIN ISO 6106 regulates the classification and designation of grain sizes for abrasives (grinding wheels, saws, cutting discs) based on two common systems: metric designation based on the mesh size of the sieves (EU) and number of sieve openings per inch (mesh, USA). This standard is based on the regulations of the FEPA (Federation of European Producers of Abrasives). The standard also specifies a method for determining or testing the grain size of diamond and cubic boron nitride.

3. Test procedure standards:

- DIN EN 725 – test method for high-performance ceramic powder: this deals with the determination of impurities, particle size distribution, density and shake density. Some standards in this series have already been replaced by analog ISO standards. Details can be found at http://www.beuth.de/de.

- DIN EN 623 – test method for monolithic high-performance ceramics: this tests for the presence of surface defects, surface roughness, determination of grain size, determination of density and porosity as well as general and structural properties. Some standards in this series have already been replaced by analog ISO standards. Details can be found at http://www.beuth.de/de.

- DIN EN 820 – test method for thermo-mechanical properties of monolithic high-performance ceramics: testing determination of bending strength, deformation under dead weight, thermal shock resistance, creep deformation due to bending stress at higher temperatures.

- DIN EN 843 – test method for mechanical properties of monolithic high-performance ceramics at room temperature: for example, material properties of commercially available structural ceramics.

- DIN EN 821 – test method for the thermophysical properties of monolithic high-performance ceramics.

- DIN EN 658 – test methods for ceramic composites, including:

- Shear strength under pressure

- Determination of compressive strength

- Determination of properties under tension

- Bending strength

Some standards in this series have already been replaced by analog ISO standards. Details can be found at http://www.beuth.de/de.