Technical ceramics for the industry of tomorrow

Technical ceramics are one of the most versatile materials available to product designers, offering the most incredible combination of properties.

Ceramic can provide electric isolation whilst at the same time transmit heat, it can be used for protection against liquid aluminium in foundries and, in the form of a soft powder, enhance high-end cosmetics. It can also reduce friction – or conversely, help to increase friction for astonishing results.

The secret of working with ceramic is to achieve a profound understanding of it so you can make smart use of its diverse possibilities, finding the right solution for each individual case or creating new approaches where none existed before.

Ceramic is more than merely a solution to a problem – it’s a veritable source of inspiration.

What possibilities could be unlocked by a material that’s as hard as diamond, lighter than steel and more wear-resistant than titanium?

What choices would unfold if we had the right material to work with – or if we had truly profound knowledge and understanding of this material?

As ceramic experts, we know that the interesting properties of ceramic materials hold the promise of a host of novel opportunities for the future to create smart solutions in the industry of tomorrow.

This is our mission. This is what we are working towards with this new ceramic page – step by step. Watch this space...

Products in use

Ballistic Ceramic

Military forces – whether on foot, land, water or in the air – require the best possible protection at the lowest possible ... Read more

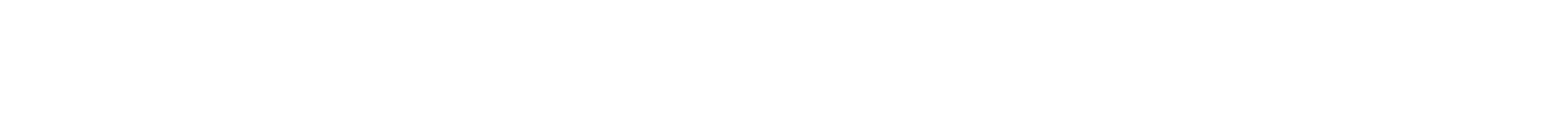

Ceramic Sliding Bearings

The ceramic material silicon carbide has a multifaceted range of properties that can be tailored to exact requirements ... Read more

Cosmetics with boron nitride

Our society places a premium on beauty. The constant search for youthfulness and a perfect appearance as ... Read more

Friction enhancing with Ceramics

Whether pressed, interlocked or bolted together: increasing the coefficient of friction makes it possible for two surfaces ... Read more

Release Agents and Lubricants

High-temperature processes – such as glass processing or metallurgical casting and forming – require release agents and ... Read more

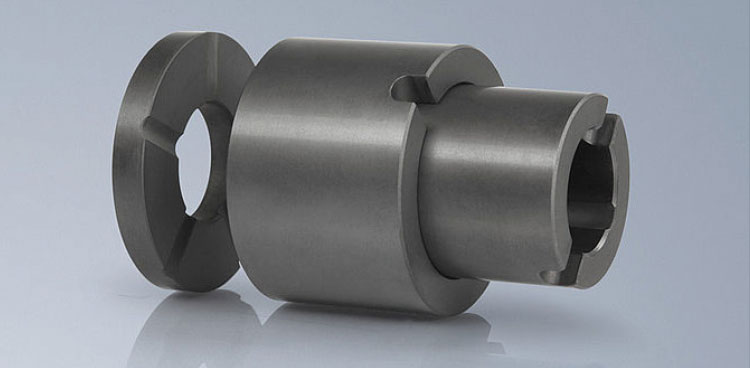

Evaporation Boats

Metalized substrates can be found in many technological as well as everyday products and applications, such as ... Read more

Thermal Management with Ceramic

Heat build-up is increasingly becoming a problem in densely designed electronic devices. Up to now, the heat ... Read more

Industry sectors

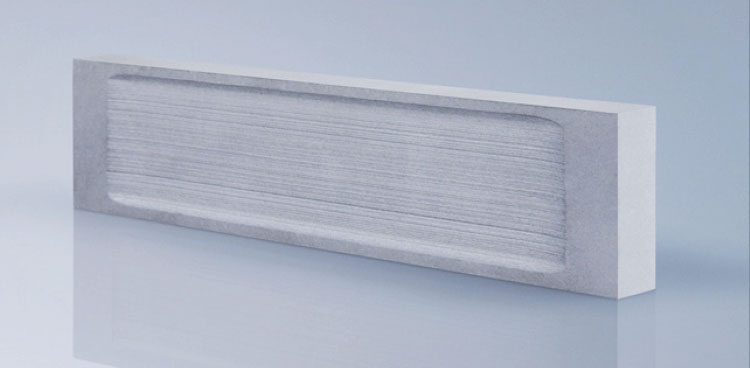

Automotive industry

There’s probably no other key sector that’s currently undergoing as rapid a transformation as the automotive ... Read more

Construction industry

With about 850,000 employees, the German construction industry generated sales of around ... Read more

Electrical industry

Germany’s electrical industry has an enormous spectrum of products in development and production. This ranges ... Read more

Cosmetic industry

The cosmetics industry is booming. In Germany alone, the market for cosmetics and personal care products continued ... Read more

Pump industry

In tandem with the companies that provide compressed air and vacuum technology and compressors, the German ... Read more

Steel and metal processing industry

Almost 20 million tons of steel – around 40 percent of the total production in Germany – are ordered every year ... Read more

Defense technology

Defense or armor technology generally makes use of the entire range of engineering sciences to develop and expand ... Read more

Case studies

Case Study

Electromobility

To the article In designing their new racing car, the s3racing team at the University of Siegen became aware of the dangers that securing the connection between the shaft and wheel hub with a simple bolt could pose in the event of sudden spikes in power. They solved this problem by introducing Friction Shims.

Case Study

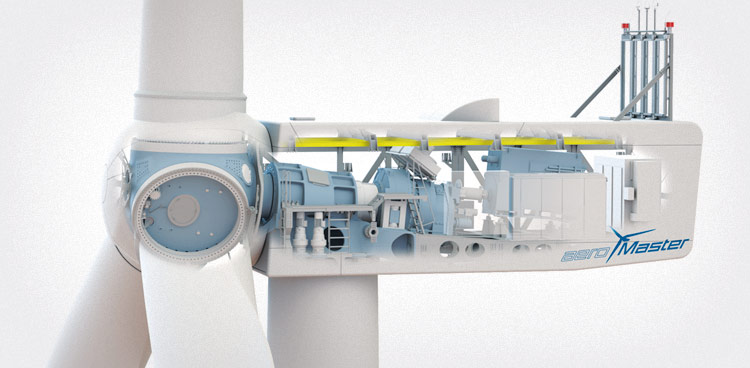

Wind power lightweight construction

To the article Onshore and offshore, new wind turbines keep getting bigger and bigger – yet at the same time, they’re also required to be lighter and smaller. There are various ways of meeting this challenge and among these, the solution of inserting foils to increase friction is showing great promise.

Case Study

Better dynamics for all-wheel-drives

To the article In designing their new racing car, the s3racing team at the University of Siegen became aware of the dangers that securing the connection between the shaft and wheel hub with a simple bolt could pose in the event of sudden spikes in power. They solved this problem by introducing Friction Shims.

Case Study

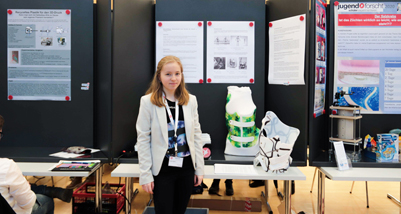

Thermal conductivity in polymers

To the article Customised scoliosis braces are used to counteract deformities of the spine at an early stage. The only problem is that they’re poor conductors of body heat – yet they must be worn permanently. Anika Spira, a 16-year-old student from Bad Sobernheim, has come up with a solution that significantly improves the comfort of scoliosis braces, especially during the warmer season.

CASE STUDY

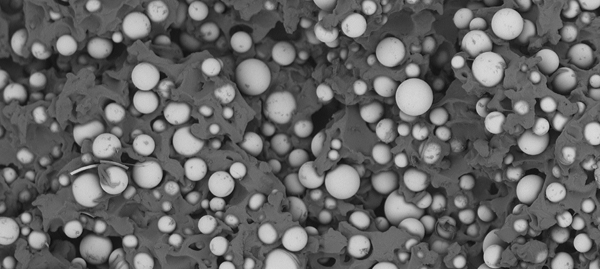

Silicon carbide – the ceramic solution for a diverse range of applications

To the article As a ceramic material, Silicon Carbide is characterized by its high strength and heat resistance, but it is particularly known for its outstanding wear resistance when used with corrosive or abrasive media. Change of views with an engineering specialist will lead to insights on a short track whether and to what extend these material advantages may be transferred to a specific component.

CASE STUDY

Triathlon miracle: Innovative new concept made with screwed carbon

To the article Experienced athletes know: The toughest rival to beat is yourself. That’s how developers at Canyon see their job. Each generation of high-performance bikes needs to be even lighter, more user-friendly, more aerodynamic. For some three years, development work and countless flashes of inspiration have been poured into the company’s latest development - the Speedmax CFR Disc triathlon bike, first time using Friction-Enhancing Shims.

CASE STUDY

Effective cooling for computer tomographs

To the article Computer tomographs (CT) play an indispensable in medicine – for diseases as well as in cancer medicine. The technology supports the doctors in diagnosis and therapy with images of the highest possible resolution in diagnosis and therapy. Additionally, to optical quality, high robustness, reliable operation and patient safety are highly required at all times. In the construction of circulation pumps for CT cooling, the Austrian manufacturer KRAL relies on plain bearings and sealing rings made of silicon carbide (SiC).

Case Study

Polymers and additives

To the article Weight, thermal conductivity, dimensional stability, burning behavior and more: Thermoplastic elastomers (TPEs) have to meet a wide variety of requirements depending on the specific application. The intelligent combination of polymers and additives makes it possible to develop targeted TPEs with the required properties.

Case Study

Production penetrates deeper and deeper sea areas

To the article Whether plastics production, pharmaceutical products, building heating or mobility: fossil fuels natural gas and oil drive our world. The extraction of these natural raw materials is therefore key in the global quest of energy transition. The Oil and Gas industry - with extraction on land (onshore) as well as offshore.

Case Study

Steel production: things only get really exciting above 1,500 °C

To the article How do you define what’s really "hot"? Like so many definitions, this depends entirely on your personal viewpoint. In steel production, for example, temperatures of 1,500 °C or more are very common. This is when system solutions from suppliers like RHI Magnesita are in demand. With its refractory technologies, the globally active group ensures safe and reliable processes.

Case Study

Sheet ceramic (“Keramikblech”): An enabler under demanding conditions

To the article It all comes down to a clever mix of materials: When individual materials reach their limits, for example in terms of their thermal or mechanical load-bearing capacity, composite materials can open up new possibilities. An apt example of this is “Keramikblech”. Behind this brand name of Pritzkow Spezialkeramik are oxide ceramic fiber composites that have long been more than an insider tip for particularly demanding application conditions.

Interviews

On the way to zero emission mobility

New drive concepts are changing vehicle architecture and placing greater demands on material combinations and lightweight construction solutions ... Read more

Two good ideas will lead you to one really special idea

We have been working with special ceramics in microwave technology for thirty years. Here we have achieved market leadership in some high-performance components ... Read more

Ceramics & plastic

We believe that there is still plenty of potential, especially where there are advantages in the direction of mechanical ... Read more

Ceramics, standards and certifications

From comprehensibility to commitment to the reliability of facts and their relationships ... Read more

Grinding with technical ceramic: in conversation with an expert

Bernhard Schmitt has been the managing director of Artur Glöckler GmbH since 2004. The now fourth generation ... Read more

3D printing with technical ceramic

When it comes to the precise manufacture of 3D objects, additive manufacturing in industrial production ... Read more