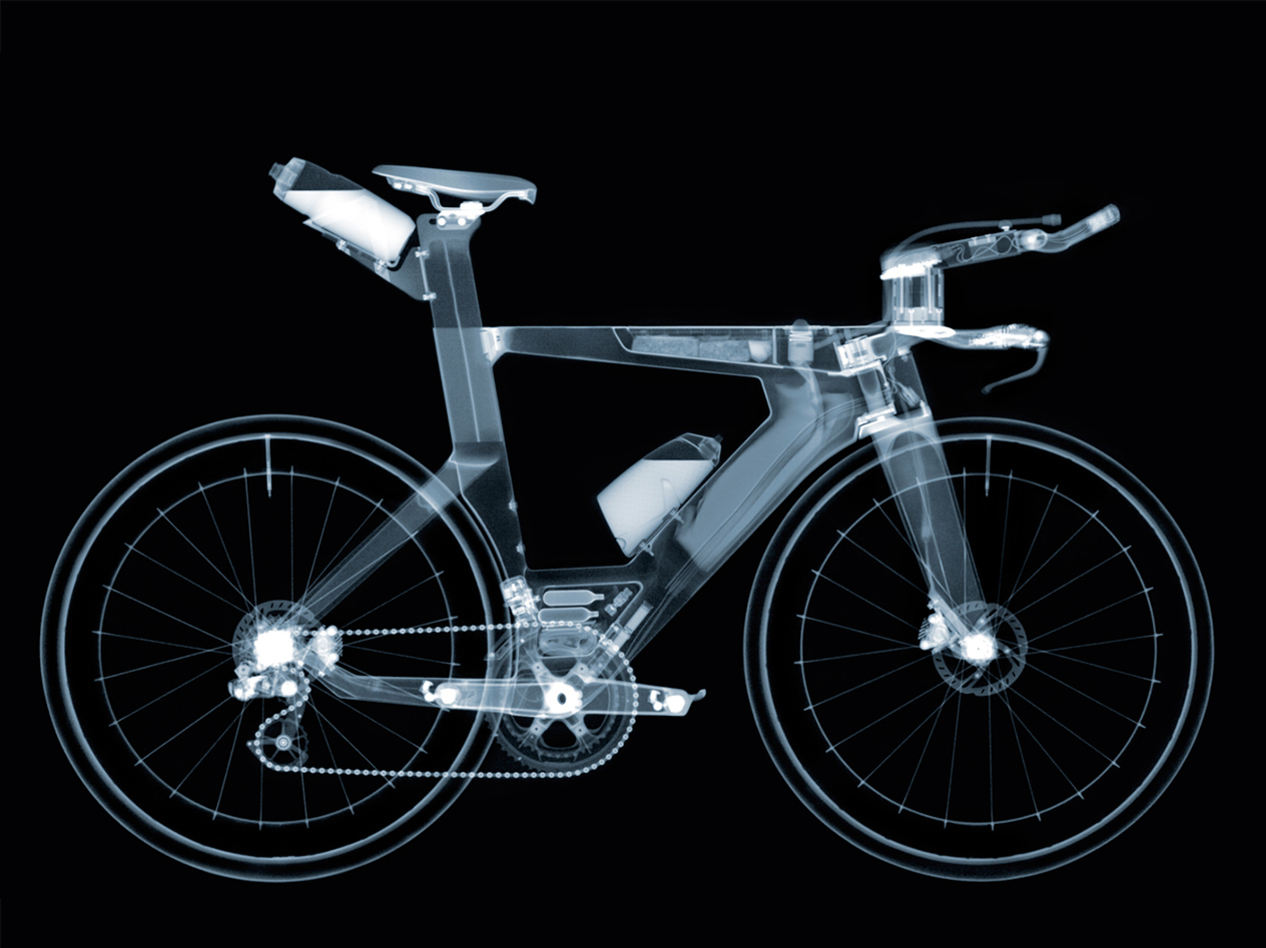

Triathlon miracle: Innovative new concept made with screwed carbon

Friction shims for triathlon bikes in the highest performance category

Previous generations of the new triathlon bike have already set the standard with victories in series and five world championship titles in a row. The next generation of Speedmax is now accelerating off the starting blocks in the forge. The addition of a “disc” is already making it clear: A Canyon triathlon bike has disc brakes for the first time. This is one decision with which developers have long been wrestling, as Daniel Heyder from Canyon explains. “Our view is clear: A disc brake only makes sense if it offers a real advantage to professional athletes”. No sooner said than done: The additional weight associated with the disc brake had to be at least compensated for elsewhere through intelligent engineering. Ultimately, every watt of energy that the professional athlete can save is literally worth its weight in gold.

A triathlon pushes man, woman and material to the max. Trailing cyclists follow their high standards and fly over the tarmac. Cycling thrives on the fascination with speed and the tight symbiosis between athlete and bike. This is where Canyon’s racing machines need to support athletes by enabling them to exploit the bike's full capacity over the entire stretch of 180 kilometers (long-distance). Triathlon bikes need to adaptable for maximum speed and optimization, to make the individual aero-position as comfortable as possible. The key here is the perfect seating position, which can be individually adjusted. When it comes to the new Speedmax CFR Disc, with its linear design, Canyon has once again improved every detail.

Further optimizing these high-performance bikes demands creativity and technical expertise from the developers. Making brave choices, using new material combinations, taking advantage of experience in other engineering disciplines, such as aircraft construction - all this goes into making the bikes even lighter and ever faster. To further reduce weight, developers also opted for a composite carbon fiber in the handlebars. But how do you guard against distortion in the face of the huge loads on the handlebar grips?

This is because only comparatively low frontal pressing forces are possible with bolted carbon fibre parts to prevent damaging the carbon. Engineers at Canyon were not willing to settle for conventional carbon assembly paste. They were seeking a solution with a longer life and, above all, with a 100 percent guarantee of increasing the friction coefficient and avoiding lower frontal pressing forces. This meant any twisting of the components on the particularly safety-relevant handlebars could be prevented.

Various approaches were discussed. The final solution literally turned out to be the only alternative. Friction shims, individually designed for this type of demand and load, ensure critical stability with their friction-enhancing effect. The first model, developed after a technical brainstorming session, proved itself on the test bench. Developers opted for a circular design with a diameter of 28 millimeters. Just a small component for the triathlon bike - but a very important one. “This decision had to be taken at a very early stage of the project as part of the safety design. The advice and implementation has exceeded our expectations,” says Canyon's Wolfgang Kohl. In his opinion, friction-enhancing measures in bike development are increasingly becoming a topic of discussion - further applications in future projects are therefore quite conceivable.

However, for the time being, the new Speedmax CFR Disc is rolling into the starting blocks and should excite some attention amongst the experts. In October 2021, it will be going the whole hog - when the next triathlon world championship is due to be held in Hawaii. Will the bike stay a nose ahead of the competition, as they say? The developers are excited and pleased with the feedback from professional athletes.

Time to rest on their laurels at last? Not at Canyon. “A few months after the market launch, we are already starting work on the design for the next generation. Ultimately, everything can be optimized even more,” says Daniel Heyder: “We aim for perfection and we strive for it every day.”

From minute 7 you can see the assembly of the handlebar with Friction Shims.