Production penetrates deeper and deeper sea areas

Highly efficient production of oil and gas even under the most difficult geological conditions

According to official statistics, a good third of the world's natural gas and oil production comes from the sea. The oceanic deposits offer enormous potential for the coming years and decades to support the energy demand and source for energy transition. With the challenges of extraction from the deep sea, the demands on the technology used to ensure economic efficiency and productivity are continuously increasing. Increasing automation is one of the defining trends in offshore production, as is the use of digital technologies and the optimization of procedures and processes in ongoing production operations. Among other things, new technologies and materials are required that enable reliable extraction even under challenging conditions.

Higher productivity in oil and gas production

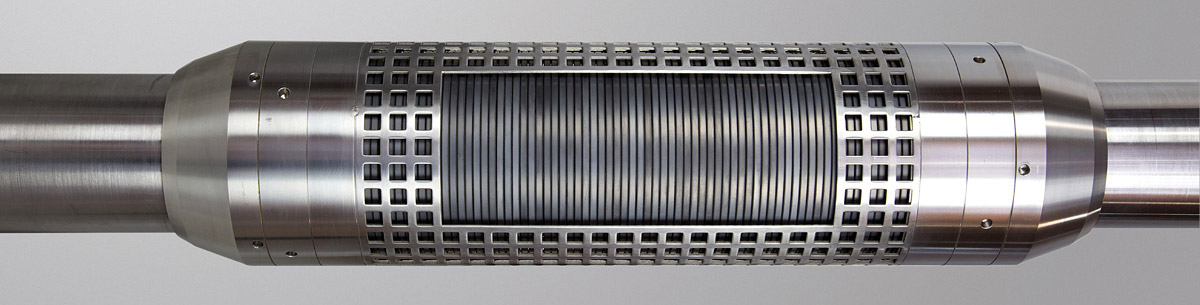

Durable, robust, and resistant: Technical ceramic parts have several properties that make them ideal for particularly demanding application conditions. Ceramic solutions can often replace other materials such as metal and have been proven to offer significantly higher productivity and robustness. A typical example of this are filter applications in oil and gas production. Sand in particular poses a permanent challenge to enabling productivity. Detrimental effects from the downhole environment and associated risk of erosion in the borehole or in the pipelines can affect production. As an erosion-resistant material, technical ceramic parts, integrated into the sand screen filter, enable effective sand control. Ceramic sand screens comprising ceramic filter parts are much more durable and reliable than conventional metallic filters or ceramic coated parts under multi- directional stress regimes. These Ceramic screen systems offer the greater operating envelope to optimize increased productivity.

Sand filters made from technical ceramics enable effective sand control

Sand screens are often used in borehole completions to prevent formation sand entraintment in the production flow. Conventional systems made of metal repeatedly prove to be susceptible to erosion with negative consequences for both productivity and the service life of the equipment. The increasing use of sand screens combining ceramic parts offers a significant improvement here: effective control of the sand in the borehole and at the same time greater resistance to various external conditions that can have a negative impact on production.

To find the right ceramic material for a downhole sand filter, four main criteria must be met:

- The system must utilize ceramic parts as the primary filter material

- The material must be designed in such a way that it allows a sufficient flow rate through the filter and at the same time retains the sand

- The material must be chemically resistant to the fluids used in production in the borehole

- The material must be highly resistant to erosion, even with vertical sand entry or at very high speeds

Technical ceramics: ten times harder than metal filters

To meet all requirements, sintered silicon carbide (SSiC) was selected as the filter component part, tested, and integrated into the construction of the sand screen system. The material offers a unique combination of properties. Outstanding hardness and compressive strength are just as much a part of this as the highest level of robustness even in demanding environments. These 3MTM Ceramic Sand Screen Systems made of silicon carbide are up to ten times harder than metal filters and are suitable for applications in the field of oil and gas extraction. The materials used show exceptional resistance to erosion and chemical corrosion, which has been confirmed by various extensive series of tests. The proven longevity of the ceramic is also confirmed by impingement velocities at high speeds.

High flexibility and simplified processes

With their high robustness, 3MTM Ceramic Sand Screen Systems are suitable for various oil and gas applications and have a high degree of flexibility in terms of meeting installation dog leg severity requirements. 3MTM Ceramic Sand Screen Systems simplify the process by eliminating the need for complex sand control techniques extending the application of use as a Stand-Alone-Screen methodology. The sand screens are suitable both for retrofitting in existing boreholes, which require higher drawdown pressures to produce the required production and for use in new field developments where formation breakdown results in sand mobilization. Different sizes and variants of filter slot openings are engineered to meet the requirements of the respective borehole application.

Successful application in Dvalin gas field development

A current project example for the advantageous use of 3MTM Ceramic Sand Screen Systems is a gas field in the Norwegian Sea. The field with its two depositional environments, Dvalin East and Dvalin West, is operated by Wintershall DEA Norge. It is characterized by dry gas, a high proportion of carbon dioxide, high temperatures of up to 160 °C and high pressure (SIWHP 620 bar). The expected sand production and flow rate could lead to severe damage to the production facilities without effective countermeasures. After extensive checks and tests with a focus on safety and quality, the choice fell on the latest generation of 3MTM Ceramic Sand Screen Systems. All wells were equipped with robust and erosion-resistant ceramic systems. The design, construction and material specifications were tailor-made for the Dvalin project, meeting the high-quality standards required under challenging conditions. The gas field development is based on four wells with open-hole sand control in 3 S-type with vertical inclination and a 630-meter-long horizontal inclination, for which the new generation of 3MTM Ceramic Sand Screen System is used. Each well produces 3 MMSCM (Million Metric Standard Cubic Meters) daily, thanks to the sand-free production, the original expectations for productivity have been exceeded. This method of well completion enables cost-effective, efficient simple sand control deployment and operation, with associated additional reduction in operational HSE risks.

Effective sand control - efficient conveyance

3MTM Ceramic Sand Screen Systems provide effective sand control to maximize flow capacity, productivity, and sand free production well life. That means more efficiency for respective oil and gas production.

3MTM Ceramic Sand Screen Systems offer:

- Resistance to high flow velocities resulting in reduced erosion, including erosional hot spot problems

- A proven sand control solution that meets the needs of the oil and gas industry, validated in laboratory testing and proven in the field of application globally

- Cost effective alternative to conventional sand control methods

- Extended sand control life

- Simplicity and flexibility in the well operator’s methodology for downhole sand control

Meet the experts on Society of Petroleum Engineers and find more specific information on Jackson, Steven Richard | SPE.

Learn more about the capabilities of SILICON CARBIDE.