Case Study

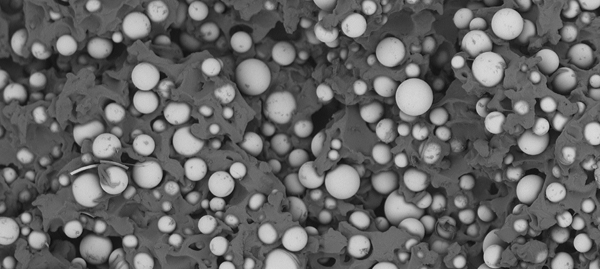

Effective overmoulding of electronics

To the article Thermoset injection moulding of electronic components combines mechanical protection with effective thermal management. Whenever electronic components are to be encapsulated in a media-tight and gentle manner, and thermal management is required, Direct Injection Moulding (DIM) – the direct overmoulding of the component – is a target-oriented solution. By using epoxy moulding compounds and specifically selected fillers such as boron nitride, it’s possible to protect components in harsh environmental conditions.

Case Study

Safe connections in hydropower plants

To the article In the course of the expansion of renewable energies, hydropower is playing a central role in Europe and worldwide. Currently, it accounts for about one-sixth of the total electricity supply used globally. The technology used in hydropower plants must function reliably and robustly for decades. The shaft-hub connections in the turbine and generator shaft area, for example, are exposed to the highest loads. Global Hydro, as one of the leading suppliers of hydropower plant technology, is breaking new ground with friction-enhancing shims. In comprehensive test series, the solution has met all requirements - or even significantly exceeded them.

Case Study

Sheet ceramic (“Keramikblech”): An enabler under demanding conditions

To the article It all comes down to a clever mix of materials: When individual materials reach their limits, for example in terms of their thermal or mechanical load-bearing capacity, composite materials can open up new possibilities. An apt example of this is “Keramikblech”. Behind this brand name of Pritzkow Spezialkeramik are oxide ceramic fiber composites that have long been more than an insider tip for particularly demanding application conditions.

Case Study

Steel production: things only get really exciting above 1,500 °C

To the article How do you define what’s really "hot"? Like so many definitions, this depends entirely on your personal viewpoint. In steel production, for example, temperatures of 1,500 °C or more are very common. This is when system solutions from suppliers like RHI Magnesita are in demand. With its refractory technologies, the globally active group ensures safe and reliable processes.

Case Study

Production penetrates deeper and deeper sea areas

To the article Whether plastics production, pharmaceutical products, building heating or mobility: fossil fuels natural gas and oil drive our world. The extraction of these natural raw materials is therefore key in the global quest of energy transition. The Oil and Gas industry - with extraction on land (onshore) as well as offshore.

Case Study

Polymers and additives

To the article Weight, thermal conductivity, dimensional stability, burning behavior and more: Thermoplastic elastomers (TPEs) have to meet a wide variety of requirements depending on the specific application. The intelligent combination of polymers and additives makes it possible to develop targeted TPEs with the required properties.

Case Study

Effective cooling for computer tomographs

To the article Computer tomographs (CT) play an indispensable in medicine – for diseases as well as in cancer medicine. The technology supports the doctors in diagnosis and therapy with images of the highest possible resolution in diagnosis and therapy. Additionally, to optical quality, high robustness, reliable operation and patient safety are highly required at all times. In the construction of circulation pumps for CT cooling, the Austrian manufacturer KRAL relies on plain bearings and sealing rings made of silicon carbide (SiC).

Case Study

Triathlon miracle: Innovative new concept made with screwed carbon

To the article Experienced athletes know: The toughest rival to beat is yourself. That’s how developers at Canyon see their job. Each generation of high-performance bikes needs to be even lighter, more user-friendly, more aerodynamic. For some three years, development work and countless flashes of inspiration have been poured into the company’s latest development - the Speedmax CFR Disc triathlon bike, first time using Friction-Enhancing Shims.

Case Study

Silicon carbide – the ceramic solution for a diverse range of applications

To the article As a ceramic material, Silicon Carbide is characterized by its high strength and heat resistance, but it is particularly known for its outstanding wear resistance when used with corrosive or abrasive media. Change of views with an engineering specialist will lead to insights on a short track whether and to what extend these material advantages may be transferred to a specific component.

Case Study

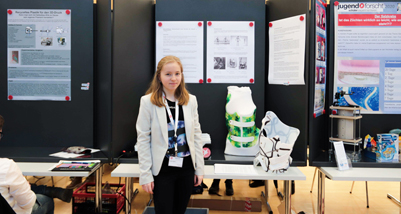

Thermal conductivity in polymers

To the article Customised scoliosis braces are used to counteract deformities of the spine at an early stage. The only problem is that they’re poor conductors of body heat – yet they must be worn permanently. Anika Spira, a 16-year-old student from Bad Sobernheim, has come up with a solution that significantly improves the comfort of scoliosis braces, especially during the warmer season.

Case Study

Better dynamics for all-wheel-drives

To the article In designing their new racing car, the s3racing team at the University of Siegen became aware of the dangers that securing the connection between the shaft and wheel hub with a simple bolt could pose in the event of sudden spikes in power. They solved this problem by introducing Friction Shims.

Case Study

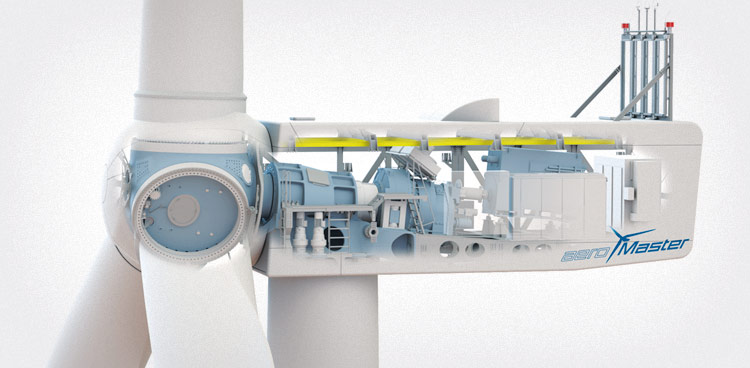

Wind power lightweight construction

To the article Onshore and offshore, new wind turbines keep getting bigger and bigger – yet at the same time, they’re also required to be lighter and smaller. There are various ways of meeting this challenge and among these, the solution of inserting foils to increase friction is showing great promise.

Case Study

Electromobility

To the article In designing their new racing car, the s3racing team at the University of Siegen became aware of the dangers that securing the connection between the shaft and wheel hub with a simple bolt could pose in the event of sudden spikes in power. They solved this problem by introducing Friction Shims.